Industrial AI at the Silicon Edge: Architectures, Agents and the Rise of Intelligent Manufacturing

- Sep 30, 2025

- 6 min read

Read Below:

Embedded AI Drives Industrial Autonomy: AI-capable microcontrollers and edge platforms are powering real-time analytics, predictive maintenance and vision-guided robotics directly on factory floors, thus reducing latency by minimizing reliance on cloud computing latency and enabling dynamic, software-defined control and automation systems.

Complete On-Premise Intelligence Pipeline: From quality control to digital twins, industrial systems now integrate sensing, ML inference and actuation within local hardware ecosystems, ensuring efficiency, security and low power consumption.

Secure, Adaptive Infrastructure Enabled by Trusted Silicon: With cryptographic MCUs and secure orchestration, AI deployments are hardened against tampering and lifecycle risks, while McKinsey Electronics’ partner ecosystem and line card ensure reliable sourcing, design support and regional scalability.

AI as a Core Driver of Industrial Intelligence

Artificial Intelligence (AI) plays a central role in modern industrial engineering. It powers real-time decision-making, automates quality inspection, enhances control loops and redefines how hardware and software interact in industrial settings. At the heart of this transformation are AI-capable microcontrollers, high-precision sensors and edge computing platforms that execute machine learning models close to the equipment they monitor.

Manufacturers now deploy industrial-grade silicon such as the Nuvoton MA35D1 or the STM32MP1 from STMicroelectronics to perform low-latency inference on-site. These platforms allow machines to learn from live process data and adapt operations dynamically without relying on remote servers. Factories increasingly resemble software-defined environments where embedded intelligence improves every decision loop.

Predictive Maintenance with AI Inference at the Edge

Predictive maintenance has become one of the most impactful applications of industrial AI. Using MEMS accelerometers from STMicroelectronics, such as the LIS2DH or LSM6DSL, engineers gather real-time vibration and inertial data from critical equipment. This data is sampled and preprocessed on ST’s STM32H7-series MCUs, which offer the compute resources necessary for signal conditioning and initial feature extraction.

Machine learning models trained for anomaly detection are deployed in lightweight form using TensorFlow Lite Micro. These models run directly on the microcontroller and classify machine conditions based on time-domain and frequency-domain characteristics. When more compute is required, the workload escalates to a National Instruments CompactRIO controller, which handles high-resolution FFT processing and ML inference using a more advanced SoC architecture.

Maintenance outcomes, including anomaly predictions and degradation trends, are transmitted over OPC UA to higher-level MES systems. Operators visualize these results in familiar SCADA environments such as AVEVA Edge or Ignition Perspective, where alerts and maintenance instructions can be scheduled automatically.

Vision-Guided Robotics with Real-Time Classification

In robotic assembly lines, machine vision is increasingly tied to embedded AI for object detection and guidance. Systems use industrial-grade image sensors from Brightek Optoelectronic to acquire high-fidelity optical data under varying lighting conditions. The captured images are processed by AI-capable microprocessors such as the STM32MP1 or Nuvoton MA35D1, both of which can run quantized object detection models like YOLOv8 in real time.

Vision-based pose estimation enables precise control over robotic pick-and-place operations. These calculations are integrated into the motion control loop through industrial communication protocols such as EtherCAT, connected to IO modules and actuators from Wago or Weipu. When parts deviate from expected alignment or orientation, corrections are made instantly without operator intervention.

As lighting or part geometry varies, retraining pipelines implemented on edge hardware allow the neural network to continue improving over time. This ensures consistent detection accuracy and optimal performance across shifts and product lines.

Digital Twins and Data-Driven Process Control

Digital twins now extend beyond structural replication to include thermodynamic and chemical process modeling in real time. In an electroplating system, engineers use data from CompactRIO systems integrated with analog modules to continuously monitor current, temperature and pH. These inputs feed into real-time LSTM neural networks deployed on embedded platforms from STMicroelectronics or Nuvoton, which forecast ion depletion and coating uniformity.

The predictions from the digital twin feed directly into Model Predictive Controllers (MPC) operating inside process automation platforms such as Siemens PCS neo. Based on the forecasts, the controllers make fine adjustments to voltage, flow rates or chemical concentrations to maintain yield and quality.

By integrating predictive modeling with closed-loop control, the digital twin framework ensures stable process behavior under varying feedstock or ambient conditions. Operators gain visibility into upcoming risks while automation systems execute proactive corrections.

AI Inference for Quality Control in Real Time

Fast production lines require intelligent inspection systems that can make immediate decisions. In beverage bottling or cosmetics filling, optical sensors from AMS Osram or Brightek detect fill levels, seal alignment or container integrity. These readings are analyzed using MobileNetV3 models compiled for embedded inference.

Edge devices built with the Nuvoton MA35D1 or STM32MP1 execute the models within 10 milliseconds. Any deviation from nominal standards is reported over Modbus TCP to programmable logic controllers, which then trigger pneumatic rejection arms. Wago control units process the commands and actuate mechanical responses in less than one cycle, ensuring high throughput with minimal false positives.

The complete pipeline—from sensing to inferencing to actuation—resides entirely within the local facility. This architecture eliminates latency, secures IP on-site and ensures consistent product quality without external cloud dependency.

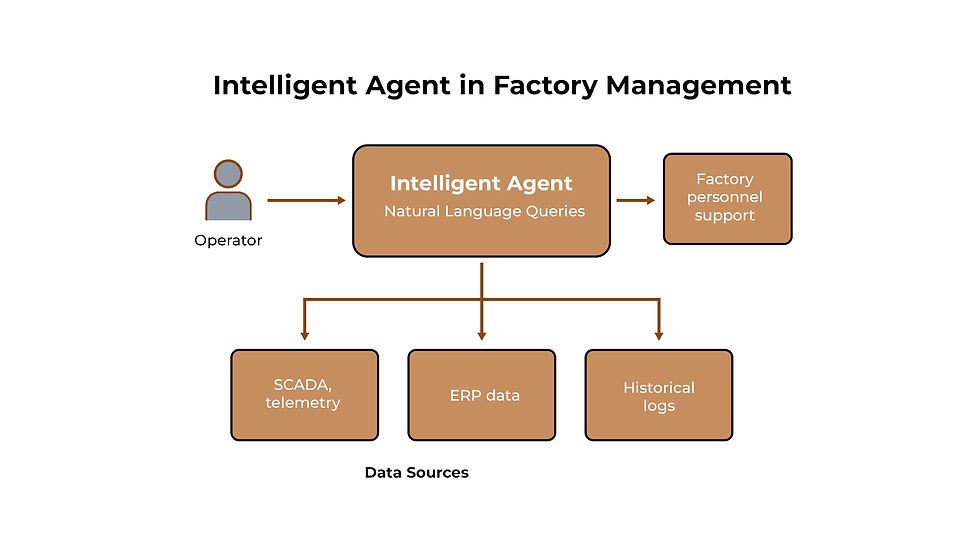

Intelligent Agents in Factory Management

Advances in industrial LLMs have enabled intelligent software agents that support factory personnel in real time. These agents run on local embedded Linux gateways, while security interfaces use Renesas RX65N MCUs, which offer hardware-based cryptographic capabilities and tamper detection.

The agents analyze historical SCADA logs, live sensor telemetry and ERP data using natural language queries. For instance, if an operator asks, “Why did OEE drop on Line 2 yesterday?”, the system correlates alarms from the CompactRIO, identifies an encoder drift on a key servo and surfaces a maintenance ticket that was delayed. Suggestions for corrective action appear instantly in the operator’s interface, streamlining troubleshooting and incident response.

This level of integration helps bridge gaps between operations, maintenance and engineering without increasing staff workload. Knowledge retention improves and critical insights are no longer locked away in log files or spreadsheets.

Hardware Programming and Embedded Design Optimization

AI enhances system design at the hardware level. Companies use BPM Microsystems programming equipment to automate firmware installation and memory testing for custom MCUs. These systems ensure high throughput and consistent reliability in production lines where thousands of units must be prepared daily.

In motor control applications, engineers using STM32 MCUs from STMicroelectronics benefit from InstaSPIN-FOC firmware libraries that support automatic tuning of PI regulators and observer models. These features are now supplemented with ML-enhanced algorithms that optimize field orientation and torque tracking dynamically based on real-time feedback. The motor controller adapts continuously to load changes and aging effects, improving performance across diverse operating conditions.

This capability is especially valuable in robotic arms and conveyor systems where precision and response speed are critical.

On-Premise Infrastructure and Power Efficiency

As AI adoption increases, factories must host more compute resources locally. Instead of relying on centralized servers, industrial teams deploy AI workloads directly on embedded platforms such as the Nuvoton MA35D1 or STM32MP1. These chips consume minimal power while supporting advanced inference frameworks.

Power delivery and distribution are managed using Wago control systems that balance loads based on production activity. For thermal regulation, heat sinks and conduction-cooled enclosures are designed around T-Global Technology materials, ensuring stable performance in rugged conditions.

The result is an energy-efficient, AI-enabled factory infrastructure that supports high performance while maintaining industrial-grade reliability.

Security and Lifecycle Management

AI models deployed at the edge require strong protections. Hardware root-of-trust is provided by Renesas secure elements or STMicroelectronics TrustZone-enabled MCUs. Firmware updates are signed using elliptic curve cryptography and pushed over-the-air through secure bootloaders managed by National Instruments orchestration systems.

Security logging and access control are managed via encrypted SCADA integration, ensuring that any model updates, configuration changes or parameter shifts are traceable and auditable. Engineers can roll back to known-good versions using version-controlled deployment pipelines, minimizing risk during experimentation or model retraining.

Industrial AI is moving from peripheral experimentation into central infrastructure. With support from Dubai-based McKinsey Electronics’ line card partners — including STMicroelectronics, Nuvoton, Renesas, Brightek, AMS Osram, BPM Microsystems, Wago and many more — engineers can build and maintain AI-native systems that monitor, control and improve their own performance.

These systems deliver more than automation; they enable learning, adaptation and resilience at the level of silicon and firmware. The factory of the future is already being shaped by intelligent components from these manufacturers, one control loop at a time.